Handcrafted Rugs, Timeless beauty.

Every Knot is a Tribute to Ancient Techniques and Skill.

Crafted with Passion, Preserving the Legacy of Generations.

Timeless Rugs that Capture the Essence of Heritage.

Crafted with Passion, Preserving the Legacy of Generations.

Timeless Rugs that Capture the Essence of Heritage.

Weaving Legacy: Preserving Centuries of Rug-Making Tradition

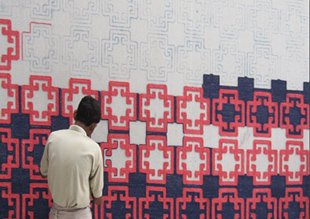

For generations, our artisans have carried forward the timeless tradition of rug-making, weaving their rich heritage into every knot. Passed down through the ages, this craft has become an art form nurtured by skilled hands and perfected over centuries. From the intricate techniques introduced by Persian travelers to today’s masterpieces, we continue to honor and preserve the legacy of hand-knotting rugs, weaving stories of culture, craftsmanship, and dedication into every design.

Types of Hand Crafted Rugs

Knotting

Knotting is an ancient technique that involves using a loom where the warp acts as the foundation of the rug. The design is formed by tying knots of colored yarns through the warp threads, following a detailed pattern. The quality of a hand-knotted rug is determined by the knot density, with more knots per square inch resulting in a finer, more intricate design. This traditional method creates durable, high-quality rugs with a rich texture and detailed artistry.

Tufting

Tufting is a technique where wool yarn or other fibers yarn like silk or viscose are punched through a canvas backing using a hand-operated tool. The yarns are pushed into the canvas, forming a pile that gives the rug its texture and depth. Once the rug is fully tufted, it’s removed from the frame, and a scrim fabric is glued to the back for stability. A fringe is added through either sewing or gluing. Tufted rugs offer a plush, soft texture and are quicker to produce than knotted rugs.

Flat Weaving

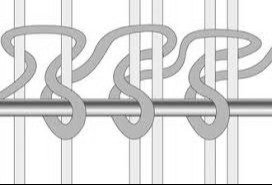

Flat weaving involves the interlacing of warp (vertical) and weft (horizontal) threads without creating a pile, unlike tufted or knotted rugs. The threads are woven directly into intricate patterns on a loom. Flat weave rugs are thinner, more flexible, and lightweight, making them easier to fold and move. They are often reversible, with the same design on both sides, and offer vibrant, colorful patterns without the extra bulk. This technique is ideal for creating durable, functional, and stylish rugs suitable for various spaces.

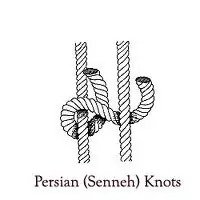

Persian Knot (Senneh Knot)

The Persian knot, also known as the Senneh knot, is one of the most popular and widely used knots in rug-making. This symmetrical knot is tied around two warp threads, allowing for fine detailing and a dense pile. It is commonly used in Persian, Indian, and Oriental rugs, contributing to a smooth texture and high-quality finish.

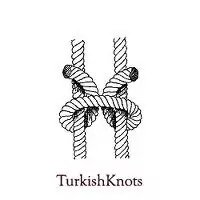

Turkish Knot (Gördes Knot)

The Turkish knot, or Gördes knot, is another highly used technique in rug knotting. Unlike the Persian knot, it is asymmetrical and involves wrapping the yarn around two warp threads. This method results in a sturdier, more durable rug with a thicker pile, and is commonly found in Indian, Turkish, and Central Asian rugs.

Tibbati Knot

The Tibbati knot is a variation of the Persian knot and is often used in Indo-Nepali rugs. It typically involves thicker yarns, creating a denser, more luxurious pile. The technique is favored for high-end rugs, particularly those made with silk or wool, and is known for producing vibrant colors and excellent durability.

Single Knot

The single knot is one of the simplest knotting methods. The yarn is tied around a single warp thread, and the knot is pulled through to secure it. It is typically used for simpler, less intricate rug designs and is faster to produce compared to other more detailed knotting methods.

Rug Manufacturing Process

Design Creation

The process begins with designing the rug’s pattern. Designers work closely with clients to understand the aesthetic, color palette, and purpose of the rug. Detailed drawings or digital mock-ups are created, defining the motifs, borders, and overall layout. This stage ensures that the final rug aligns with the vision and space it will occupy.

Material Selection

Selecting the right materials is crucial to the quality and durability of the rug. High-quality wool, silk, cotton, or synthetic fibers are chosen based on the desired texture, durability, and aesthetic. Each material brings its own unique feel, with wool providing softness and warmth, while silk offers a luxurious sheen. Natural dyes may also be selected for rich, long-lasting color.

Yarn Dyeing

The warp threads form the foundation of the rug and are stretched tightly on the loom. These vertical threads provide structure and support. The weft threads, which run horizontally, are woven through the warp, creating the foundation of the rug’s body. This step ensures the rug will have the right tension and shape for knotting.

Knotting

Knotting is the most intricate part of rug making. Each knot is tied by hand around the warp threads to create the design. The type of knot (such as Persian or Turkish) affects the texture and quality of the rug. This step requires exceptional skill and patience, as thousands of knots must be tied precisely to bring the design to life.

Weaving the Pile

Once the knots are tied, the weft threads are woven across the rug, and the pile is formed. This step adds depth and texture to the rug, and the pile’s density directly impacts the rug’s softness and durability. The weaver ensures the pile is consistent and even, resulting in a smooth surface.

Washing and Dye Setting

The rug is washed to remove any remaining impurities and to set the dyes. This process enhances the rug’s colors and softens the fibers, making the rug more comfortable to the touch. Natural dyes are carefully treated to ensure they remain vibrant over time, and any finishing treatments are applied to increase durability.

Trimming and Shearing

After the rug is woven, the pile is carefully trimmed and sheared to create an even, smooth finish. This step enhances the rug’s texture and adds depth to the design. It also helps to reveal the full beauty of the pattern, as the fibers are aligned and any excess yarn is removed.

Final Inspection and Quality Control

Once the rug is fully completed, it undergoes a rigorous inspection process. Every knot, edge, and detail is checked to ensure the rug meets high standards of craftsmanship. Any imperfections are corrected, and the rug is given a final cleaning to ensure it’s pristine. Only after passing this inspection is the rug ready for shipment or installation.

TYPE OF MATERIALS – YARN

Our rugs are crafted from a wide range of fibers, each selected for its unique qualities, appearance, and durability. The choice of materials significantly impacts the texture, aesthetics, and longevity of the rug. Here’s a deeper look at the most commonly used

Get In Touch